The company XARION has developed an optical microphone for the contactless detection of ultrasonic waves. According to the company, this opens up new possibilities for process monitoring in manufacturing, for example in 3D printing.

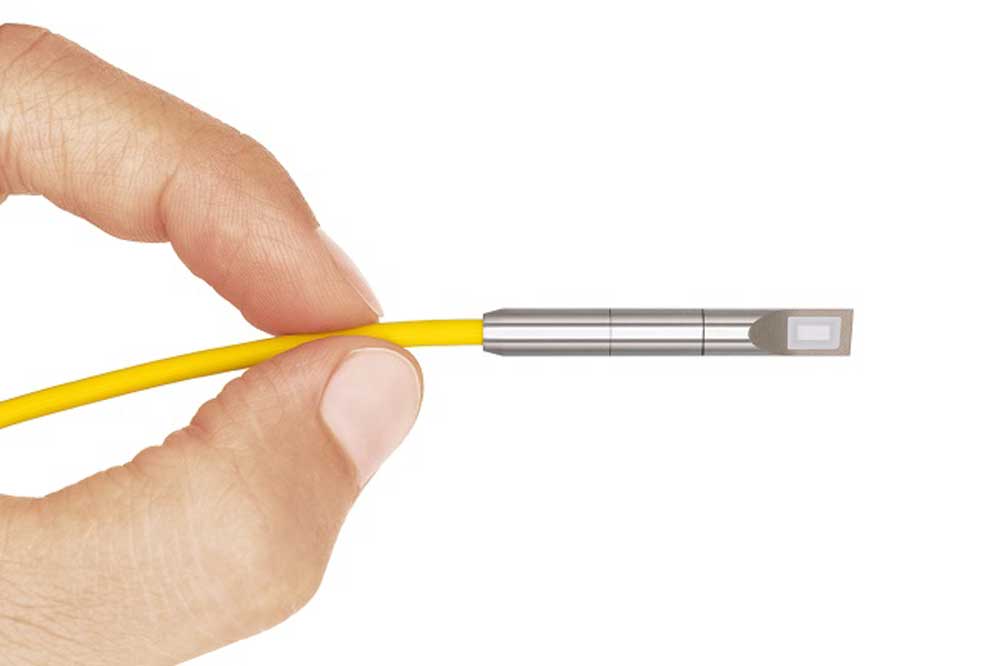

Unlike conventional sensors, the optical microphone can detect frequencies from a few hertz to two megahertz. The compact sensor head can be easily integrated into production equipment.

As Ryan Sommerhuber of XARION explains, the ultrasonic microphone can be used to measure and analyze characteristic acoustic signatures of manufacturing processes in isolation. This enables the early detection of errors.

The monitoring solution is particularly suitable for processes such as laser welding or additive manufacturing. In 3D printing, for example, cracks in components can be detected in real time, says XARION expert Jan Berger. For customers, the company offers a measurement system bundle for process monitoring.

In addition, the optical microphone is used in non-destructive material testing. According to company founder Balthasar Fischer, the contactless technology enables integration into automated inspection systems or use on robots.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.