US-based space startup Ursa Major is advancing additive manufacturing to develop next-generation rocket engines. The company recently secured additional funding from America Makes, a US 3D printing initiative, as part of an existing partnership.

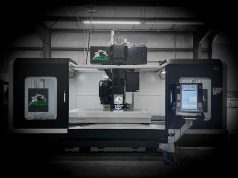

Together, the partners have been operating an advanced manufacturing lab in Youngstown, Ohio since 2021. Here, Ursa Major utilizes a large-scale metal 3D printer.

This enabled the production and testing of combustion chamber prototypes for the Hadley vacuum engine. Thanks to 3D printing the heat-resistant NASA alloy GrCop42, the manufacturing process was significantly accelerated.

According to Brad Appel, CTO of Ursa Major, the lab is of central importance. It allows a production cycle of just one month for the combustion chambers, while this process takes six months conventionally.

The partnership with America Makes will now be continued until mid-2024. The focus is on efficient serial production and qualification of engine parts to achieve market readiness. The long-term goal is to further reduce development and production times through 3D printing.

According to the company, Ursa Major’s rocket engines already consist of over 80 percent 3D printed components. Additive manufacturing is thus a key technology for the startup’s ambitious innovation efforts in the space industry.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.