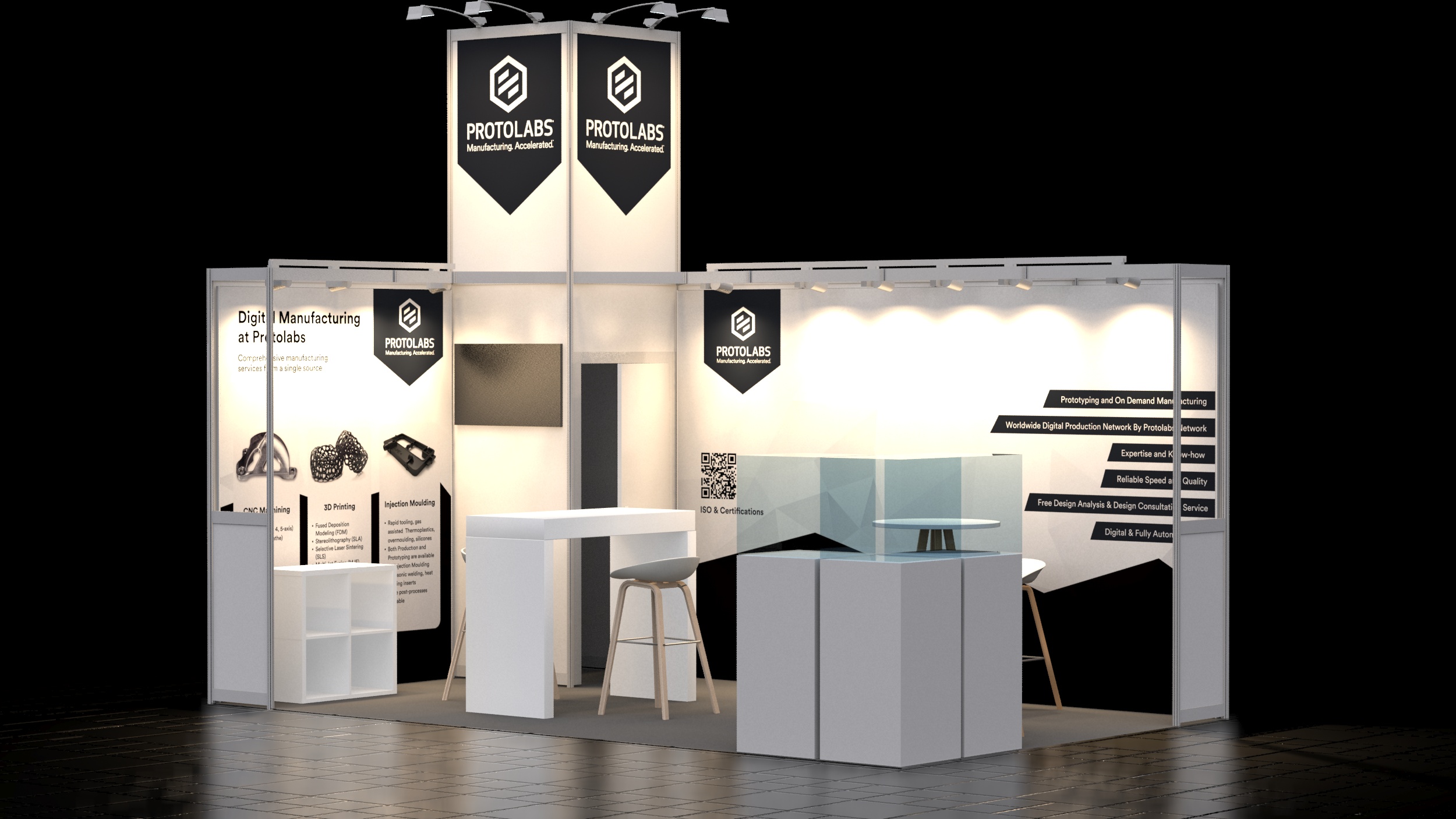

Protolabs, an international provider of digital manufacturing services, is taking part in the 29th Fakuma 2024 in Friedrichshafen. The trade fair, which takes place from October 15 to 19, will focus this year on innovative technologies in plastics processing, sustainable production processes and intelligent automation solutions. Protolabs will be represented in Hall B1, Stand B1-1126, where a team of experts will present the latest developments in CNC milling, 3D printing and injection molding.

A central element of the exhibition is the Protolabs Network, a comprehensive manufacturing concept that gives customers access to a global network of manufacturers. This network offers a wide range of manufacturing capacities, flexible pricing structures and the ability to produce individual quantities efficiently.

“The combination of our own production facilities and our international network of partners – the Protolabs Network – enables greater flexibility, sustainability and efficiency for our customers,” explains Daniel Cohn, Managing Director & 3DP Lead EMEA. “All this, combined with the extensive engineering know-how of our experts at Protolabs, enables us to achieve the best possible results for our customers – while at the same time accelerating product development and reducing costs. We are therefore proud to be able to present our Protolabs Network at the 29th Fakuma and showcase the resulting opportunities to a broad specialist audience.”

Another focus is on sustainability in manufacturing. Protolabs has expanded its offering to include recycled plastics, both in CNC and injection molding. This initiative helps customers to develop environmentally friendly prototypes without having to compromise on modern materials.

“It was crucial for us to make our production capacities as sustainable as possible for our customers,” explains Daniel Cohn. “We have therefore expanded our range in recent months to include additional plastics made from recycled materials – both in CNC and injection molding. For our customers, this means one thing above all: prototypes can be produced with state-of-the-art materials, while at the same time the sustainability aspect can be kept in mind through extensive recycling.”

Protolabs is characterized by its extensive expertise, which enables customers to choose the optimal production method for their projects. With over 25 years of experience, the company often acts as an external research and development department, supported by a Technical Consultative Sales Approach. This approach shortens development times and speeds up the market launch of new products.

“Our expertise and specialist knowledge are an invaluable added value for our customers, making the seemingly impossible a reality,” concludes Daniel Cohn. “With more than 25 years of experience, we offer our customers more than just pure consulting services. We often act as an external research and development department and our Technical Consultative Sales Approach enables an optimized product development process and thus a shorter time to market. Our focus is on enabling our customers to turn their ideas into reality in the best possible way and to exploit the full potential of production through the best possible choice of materials and production processes. This is exactly what we want to emphasize at our stand at the 29th Fakuma.”

Protolabs’ participation at Fakuma 2024 offers the opportunity to present its advanced 3D printing solutions to a broad professional audience and demonstrate the benefits of digital manufacturing technologies. Trade visitors are invited to visit the Protolabs team in hall B1, booth B1-1126, to learn about the latest developments in additive manufacturing.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.