Xact Metal, a company specialising in metal 3D printing, today announced its partnership with PanOptimization. The aim of the collaboration is to expand access to affordable metal 3D printing solutions for small and medium-sized companies and to decentralise additive manufacturing. The focus is on the integration of PanOptimization’s advanced simulation software PanX, which performs thermomechanical simulations in an innovative way.

“At Xact Metal, we’re establishing a new level of price and performance in metal 3D printing by taking the essential specs of metal additive manufacturing and combining them with breakthrough technology,” said Juan Mario Gomez, CEO of Xact Metal. “We are pleased to partner with PanOptimization to bring cutting-edge simulation and optimization into the additive manufacturing industry.”

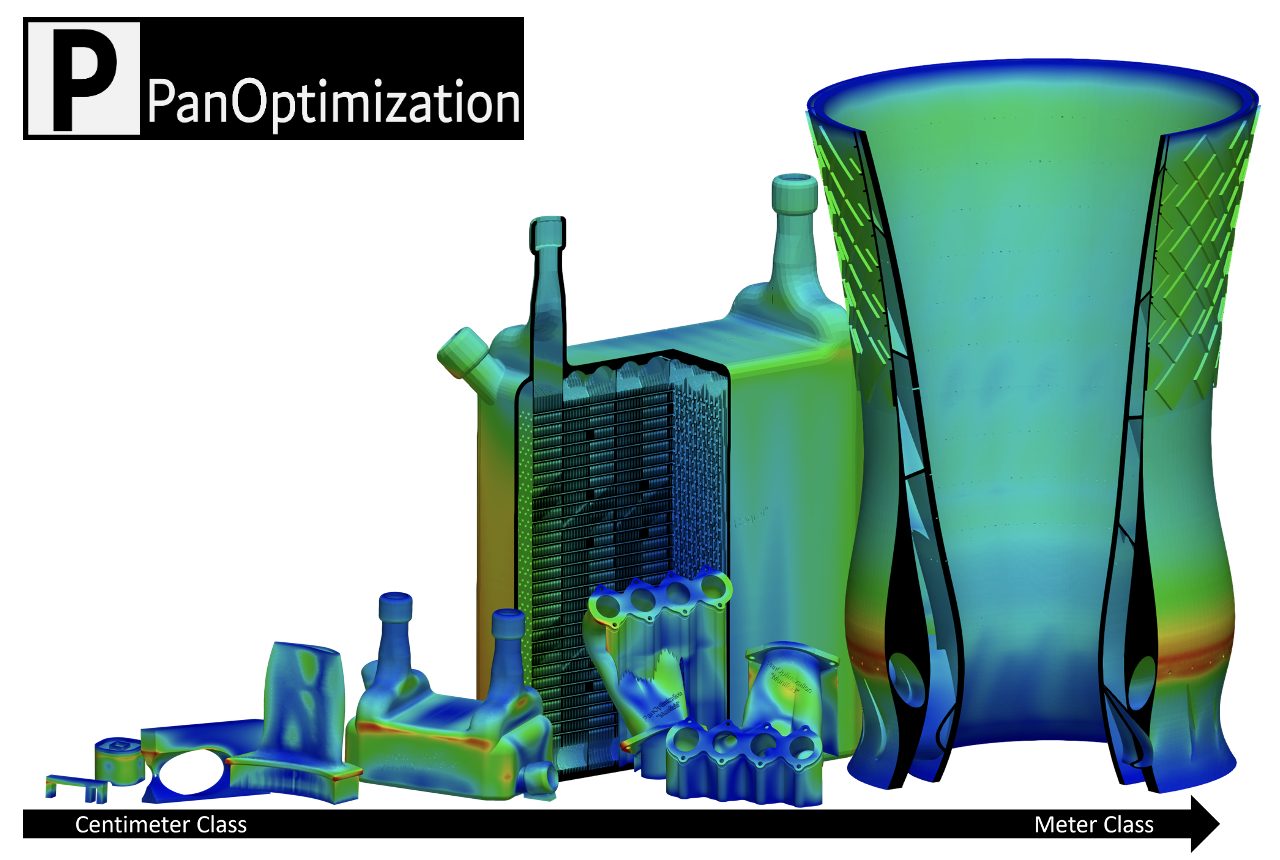

The PanX software from PanOptimisation uses a multigrid model for thermomechanical simulations, which achieves significantly higher accuracy with considerably shorter runtimes compared to conventional finite element models (FEA). In addition, the software requires only low hardware resources, which makes it particularly attractive for small companies.

PanX identifies and fixes the most common problems that occur in metal 3D printing, such as distortions, recoater clogging and cracks. This reduces the need for costly experimentation and significantly improves production quality. Gomez adds that the software is already being used to optimise the performance of their metal powder bed fusion systems and improve the mechanical properties of printed parts.

“In our drive to lower the price of additive manufacturing metal powder-bed fusion systems, we have used PanX to help us improve the performance of our systems, understand the behavior of the metals that we work with, and optimize the parts that we are printing to achieve the geometric performance that we require,” said Gomez. “We ourselves have seen the value that PanOptimation’s software provides and want to bring this benefit to our manufacturing customers, such as those in the injection molding industry, supported through our sales network of over 26 partners around the world.”

“We’re excited to begin our partnership with Xact Metal,“ said Pan Michaleris, CEO of PanOptimization. “It is a logical next step in our strategy to integrate our PanX software product line with all major machine OEMs, and an opportunity for us to go beyond our aerospace and defense user-base and expand into the broader industry of affordable metal additive manufacturing.”

The collaboration aims to further increase the efficiency and cost-effectiveness of metal 3D printing, making it accessible to a wider customer base.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.