Researchers at the University of Warwick have published a paper covering a micro-SLA 3D printing process to produce functional piezoceramic materials.

The geometry and shape of piezoelectric ceramics can directly influence their functional properties. When compressed, an electrical response can be created or, vice versa, it can respond to electrical impulses by changing shape. They are used for applications such as ultrasound scanners, fuel injector or air bag sensors to name a few.

The current approaches to produce these ceramics are limited in shapes and structures that can be produced, thus limiting the type and amount of information that can be obtained. Therefor, a greater freedom in design and geometry could offer improvements in the performance of many devices. This is why the team of engineers in the Digital and Material Technologies Laboratory has come up with a new approach to produce these small objects by using 3D printing technology with a novel piezoceramic material.

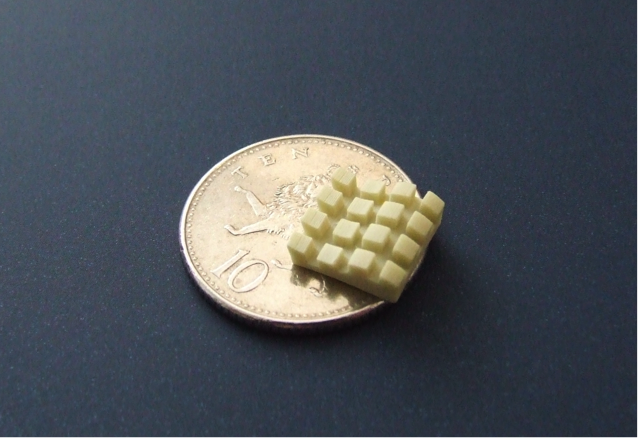

The engineers used SLA 3D printing, where a light-sensitive material is solidified layer by layer using a light source. The material used is a mixture of ceramic and light-sensitive polymer. The polymer is later removed by placing the printed object in a furnace, resulting in a solid ceramic object.

According to Simon Leigh, Assistant Professor at the University of Warwick and Head of the Digital and Materials Technologies Laboratory, the next step in this work is to generate a library of materials and scale-up the process for making much larger ceramic components.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.