Cooksongold, a precious metals company, has established a new industrial division to advance the use of additive manufacturing (AM) with precious metals. The newly formed division, Cookson Industrial, will not only provide consultancy and research, but will also cover new product development and production. Manufacturing will include both traditional and subtractive processes, all co-ordinated from the Birmingham headquarters.

The use of precious metals in additive manufacturing opens up new possibilities for applications in extreme environments where conventional alloys reach their limits. Cookson Industrial aims to help companies minimise development risks, simplify supply chains and reduce time to market.

Nikesh Patel, Head of Cookson Industrial, comments: “While the use of precious metals in additive manufacturing has largely been confined to the jewellery, luxury lifestyle industries, many more organisations are beginning to explore its potential for use in critical applications.”

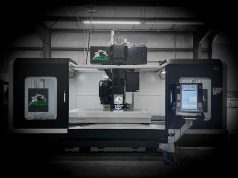

The company produces a wide range of precious metal powders on site, including gold, silver, platinum and palladium. These powders are extracted from recycled sources where possible. Cookson Industrial offers these powders in batches of up to 15 kilograms, which can either be purchased or used at its in-house production facility in Birmingham. The facility has several state-of-the-art AM machines, including six EOS Precious M 080 and M 100, as well as a Renishaw AM 500S Flex.

In collaboration with the University of Birmingham, Cookson Industrial is researching the development of precious metal alloys for additive manufacturing in aerospace, healthcare and fibreglass production. This project has been supported by a £750,000 grant from the Engineering and Physical Sciences Research Council (EPSRC).

Nikesh continues: “For extreme environments such as aerospace, where there is no room for compromise, the performance characteristics of precious metals can offer a whole new world of design parameters compared to traditional alloys. There is also a lot of dynamism in the UK aerospace sector with many legacy processes set for disruption. However, given the significant cost of the powders themselves – a full hopper often outweighs the purchase price of the AM machine – many organisations have struggled to fully commit to R&D. As we produce and print with our own powder supply, we can help derisk the process by offering the optimum parameters for powder production, storage and use. This will help reduce powder loss and the associated impact on project costs, while giving organisations access to one of the most innovative production environments in the UK.”

In addition to scientific research, Cookson Industrial also works with companies such as Bentley Motors to produce components for exclusive vehicle lines. However, the aerospace sector is considered to be particularly high growth as precious metals have the potential to replace conventional alloys and improve performance in extreme environments.

The production environment in Birmingham is one of the most advanced in the country and offers companies exploring 3D printing with precious metals the opportunity to minimise risk and optimise their processes.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.