Researchers at Carnegie Mellon University are developing numerical models that enable precise control of the 3D ice printing process for biomedical and manufacturing applications.

Nevertheless, the production of structures with precise, microscopic cavities and channels remains a challenge. Particularly in the field of tissue engineering, scaffolds must contain complex, three-dimensional networks of channels that replicate the human vascular system. Traditional additive manufacturing methods reach their limits here, as they make it difficult to create such intricate internal structures without sacrificing time, accuracy and resources.

To solve this problem, professors Philip LeDuc and Burak Ozdoganlar are developing what is known as 3D ice printing (3D-ICE). This technique uses water as the printing material, which is applied through a piezoelectric ink nozzle in the form of tiny drops onto a platform held below the freezing point. The droplets freeze immediately after contact, gradually forming an ice structure.

“3D ice could be used as a sacrificial material, which means we could use it to create precisely-shaped channels inside of fabricated parts,” said LeDuc. “That would be useful in a lot of areas, from creating new tissues to soft robotics.”

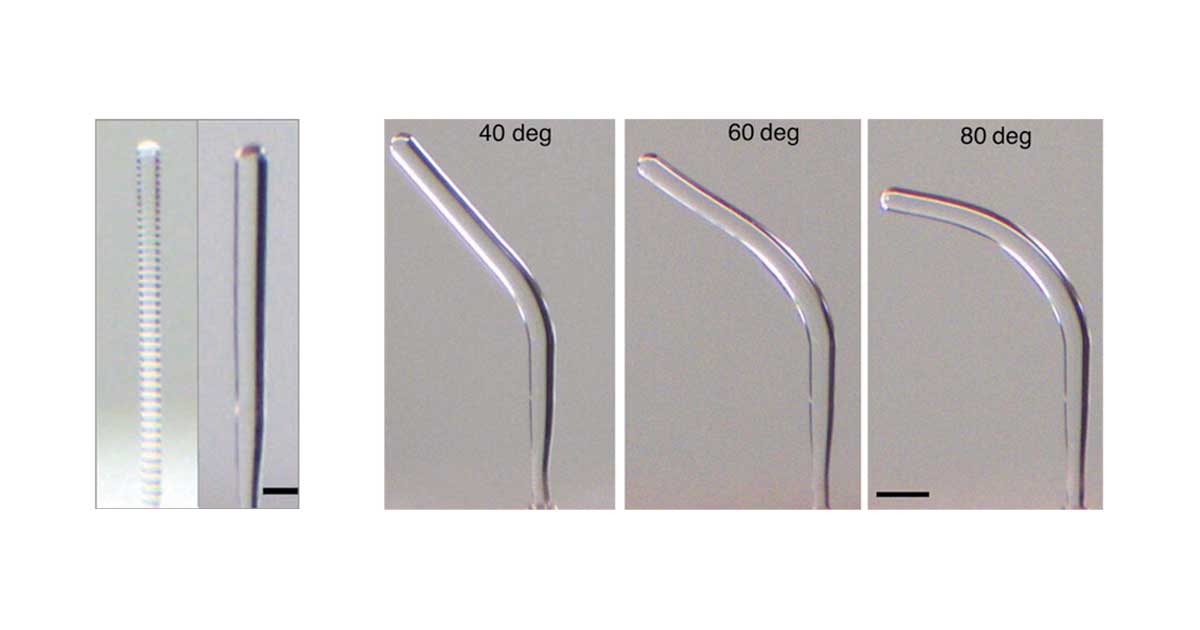

A unique feature of this process is the ability to release multiple drops before the previous one is completely frozen. This leaves a cap of water on the printed structure as the freezing progresses from the bottom to the top. This allows the creation of structures with smooth walls, transitions and branches. The dimensions of the structures can be adjusted by controlling the droplet deposition rate and the temperatures of the printing surface, the droplets and the working environment.

“The frequency of droplet deposition affects the height and width of the structure,” said Ozdoganlar. “If you deposit quickly, the water cap grows, producing wider structures. If you deposit slowly, then the structure becomes narrower and taller. There are also effects from the substrate temperature. For the same droplet deposition rate, a lower substrate temperature produces taller structures.”

LeDuc and Ozdoganlar have published their research results in the journal Proceedings of the National Academy of Sciences. The articles describe detailed 2D and 3D models that explain the physics of 3D ice printing, including heat transfer, fluid dynamics and the rapid phase change from liquid to solid. The printed ice structures can be immersed in a pre-cooled, curable resin solution. Once the resin has cured, the ice is melted and sublimated, leaving a porous mold in the resin.

“You have all types of heat transfer, including conduction to the bottom and convection to the surrounding area,” said Ozdoganlar. “All those things are working simultaneously when you deposit each droplet. If you deposit obliquely, part of the droplet spills over on the side of the pillar before it freezes. And as you keep depositing at that angle, the freeze front slowly changes shape, and the structure grows in that direction.”

In addition to refining their mathematical models, LeDuc and Ozdoganlar’s labs are working to scale up 3D ice printing and explore its effectiveness in various applications. For example, the current tissue engineering strategy could soon enable personalized tissues through 3D ice printing that replicate the unique structure of each patient’s vascular system to meet the body’s specific needs. In addition, 3D-ICE could create functional tissue constructs for research into various diseases or the development of new therapeutics.

“When I first started my lab, I would never have imagined that we would be 3D printing ice, and using it to create tissues to help people,” said LeDuc. “But our research has evolved. It has brought people like Burak and myself together, and everyone brings all sorts of different perspectives and capabilities to the table. It’s a wonderful thing to do this work together where the sum of the parts is definitely greater than the individual parts in this transdisciplinary science and engineering.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.