3D printing users are familiar with the problem: at the start of a printing process, the printer has to eject filament to clean and fill the nozzle. This so-called ‘purge line’ is usually placed at a fixed position on the print bed. A new approach now promises to improve this technology for all 3D printers.

The idea originally comes from the KAMP (Klipper Adaptive Meshing Purging) extension for Klipper firmware. KAMP adaptively places the purge line next to the object to be printed. This offers several advantages: It prevents damage to a specific location on the print bed, reduces problems with uneven print beds and minimises nozzle movement before printing begins.

Michael from the YouTube channel ‘Teaching Tech’ has now developed a method to implement this adaptive purge technique in common slicers such as OrcaSlicer, Bambu Studio and PrusaSlicer. The approach uses slicer variables to determine the position and size of the print object and place the purge line accordingly.

The implementation is done by adapting the start G-code in the printer profile. Variables such as ‘first_layer_print_min’ and ‘first_layer_print_max’ are used to position the purge line relative to the print object. The code can be easily integrated into existing printer profiles.

Tests on various printers and firmware versions show that the method works reliably. It is compatible with Klipper, Marlin and other firmware versions. Only Cura users cannot currently use the technology, as the slicer does not support all the required variables.

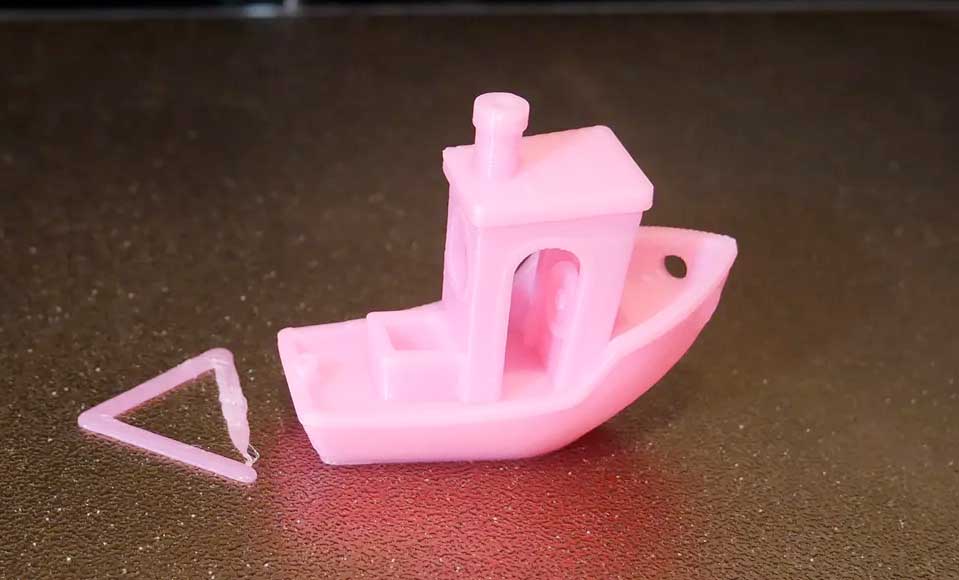

The adaptive purge technology is easy to customise. Users can modify the distance to the print object, the extrusion rate and the retraction settings as required. More complex purge patterns are also possible, such as an equilateral triangle.

Michael provides detailed documentation and sample codes on a Printables page. He emphasises that the development builds on the work of Kyle Iser for KAMP.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.